Comparison:

atmospheric or vacuum cladding

Although atmospheric cladding is an effective process there appear to be advantages if the explosive bonding process is carried out under vacuum. Besides the fact that a vacuum process is much more quiet, its greatest advantage is that it’s not necessary to remove any air between the plates during the explosion.

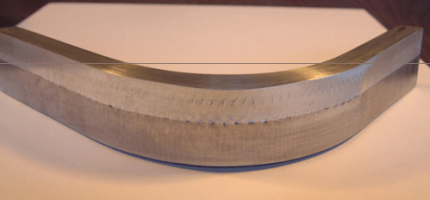

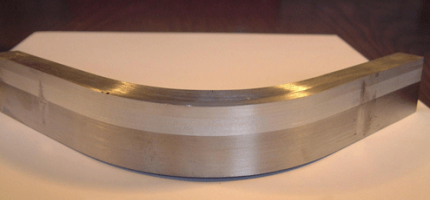

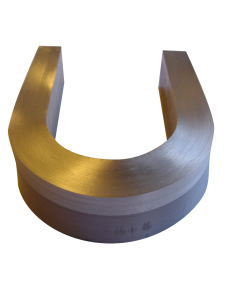

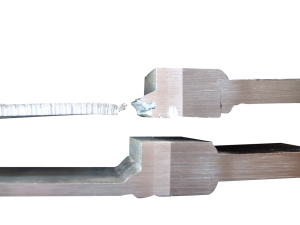

For this reason less violent explosives can be used for bonding. This produces a smoother wave bond between the aluminium and steel which is often barely visible. A turbulent wave motion can trap oxides resulting in 'holes' being visible in the bond zone. These are in fact, undesirable agglomerations of oxides as shown in the illustration. If this product is subjected to the hammer bend test it can be seen that the fractures initiate at these points. Vacuum clad products do not have this problem. The table below shows the comparative properties of atmospheric and vacuum clad products.

Summary of differences:

Open air cladding | Vacuum cladding |

|---|---|

Oxides with porosity Oxides initiate fractures Holes initiate corrosion Stress relief treatment due to cold working Variable weather conditions Harder to machine (sawing and bending | 100% dense Does not apply Does not apply Not necessary since cold working is very limited Does not apply since it is inside Easy sawing and forming due to high ductility |

Testing:

Triplate® meets the requirements of all the international standards, including the MIL-J-24445A, for Military applications.

Shear strength base material - interlayer: | > 55 N/mm2 |

Bend test base material in compression | acceptable |

Bend test base material in tension: | acceptable |

Bend test base material in tension: | acceptable |

Tensile strength (trough thickness): | > 75 N/mm2 |

Processing temperature: | max. 315° C |